Demystifying POF Shrink Film Machines: A Comprehensive Guide

POF shrink film machine is essential equipment in various industries for packaging products securely and professionally. Understanding how these machines work and their benefits can help businesses make informed decisions when investing in packaging solutions. In this comprehensive guide, we will delve into the intricacies of POF shrink film machines, shedding light on their functionality, applications, and advantages.

What is a POF Shrink Film Machine?

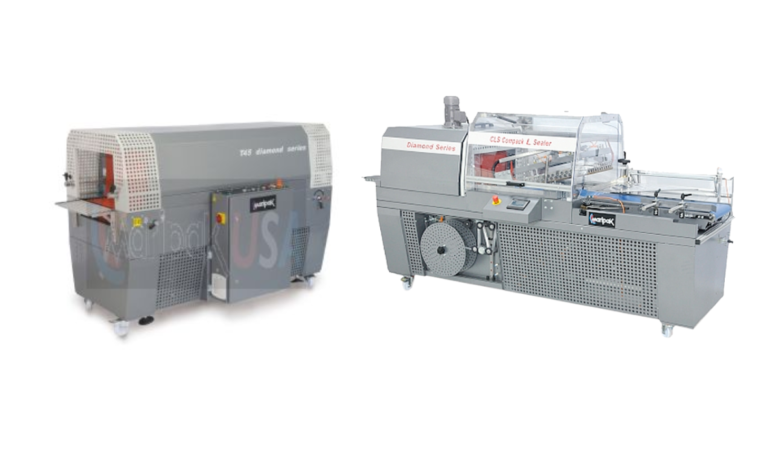

POF (polyolefin) shrink film machines are packaging systems designed to wrap products in a protective film and shrink them tightly using heat. These machines utilize polyolefin shrink film, which is a versatile and durable material known for its high clarity, strength, and shrinkage properties. POF shrink film machines typically consist of a sealing system, a heat tunnel or chamber, and conveyor systems for product transportation. Shrink Tunnel houses heating elements that generate hot air, causing the POF film to shrink and tightly wrap around the product.

How Do POF Shrink Film Machines Work?

- Sealing Process: The process begins with the product being placed on a film sheet. The edges of the film are then sealed using heat, creating a bag or sleeve around the product. This sealing process ensures that the product is securely enclosed within the shrink film.

- Shrinkage: Once sealed, the product is passed through a heat tunnel or chamber. The heat causes the shrink film to shrink tightly around the product, conforming to its shape and providing a snug fit. This shrinkage process not only protects the product from external elements but also enhances its presentation.

- Cooling: After the shrinkage process, the product is cooled to set the film and ensure a secure and tamper-evident seal. This cooling phase prevents the film from shrinking further and maintains the integrity of the packaging.

Applications of POF Shrink Film Machines

POF shrink film machines find applications across various industries due to their versatility and effectiveness in packaging. Some common applications include:

- Food Packaging: POF shrink film machines are widely used in the food industry for packaging perishable items such as fresh produce, meats, and baked goods. The transparent film provides excellent visibility of the packaged products while preserving their freshness and quality.

- Cosmetics and Personal Care Products: Many cosmetic and personal care products require attractive and tamper-evident packaging to appeal to consumers. POF shrink film machines can efficiently package items such as shampoo bottles, skincare products, and perfume boxes, ensuring product integrity and enhancing shelf appeal.

- Electronics: Electronic devices and components often require protective packaging to prevent damage during transit and storage. POF shrink film machines can package items such as cell phones, tablets, and computer accessories securely, providing cushioning and protection against moisture and impact.

Benefits of POF Shrink Film Machines

- Versatility: POF shrink film machines can accommodate a wide range of products, sizes, and shapes, making them suitable for diverse packaging needs. Whether packaging individual items or multipacks, these machines offer flexibility and efficiency.

- Enhanced Product Presentation: The tight and transparent shrink film enhances the appearance of packaged products, making them more visually appealing to consumers. This professional presentation can contribute to increased sales and brand perception.

- Tamper-Evident Packaging: POF shrink film creates a tamper-evident seal around the product, providing reassurance to consumers that the contents have not been tampered with. This feature is particularly important for food and pharmaceutical products, where product safety and integrity are paramount.

- Protection and Durability: The shrink film provides a protective barrier against dust, moisture, and other contaminants, ensuring that the packaged products remain in optimal condition during storage and transit. Additionally, the durable nature of POF shrink film helps prevent punctures and tears, further safeguarding the contents.

- Cost-Effectiveness: POF shrink film machines offer cost-effective packaging solutions compared to traditional packaging methods. By reducing material waste and improving packaging efficiency, businesses can lower their overall packaging costs and improve their bottom line.

Conclusion

POF shrink film machines are invaluable tools for businesses looking to streamline their packaging processes and enhance the presentation and protection of their products. With their versatility, efficiency, and numerous benefits, these machines offer a practical solution for packaging a wide range of products across various industries. By investing in a POF shrink film machine, businesses can improve their packaging operations, meet consumer demands, and gain a competitive edge in the market.