How Do Industrial Automation Parts Improve Efficiency in Manufacturing?

Industrial automation parts are revolutionizing the manufacturing industry by enhancing efficiency and productivity. These components play a crucial role in modernizing factories and enabling them to operate with higher precision, speed, and consistency. In this blog post, I will explore how industrial automation parts contribute to improving efficiency in manufacturing, providing you with a comprehensive understanding of their benefits.

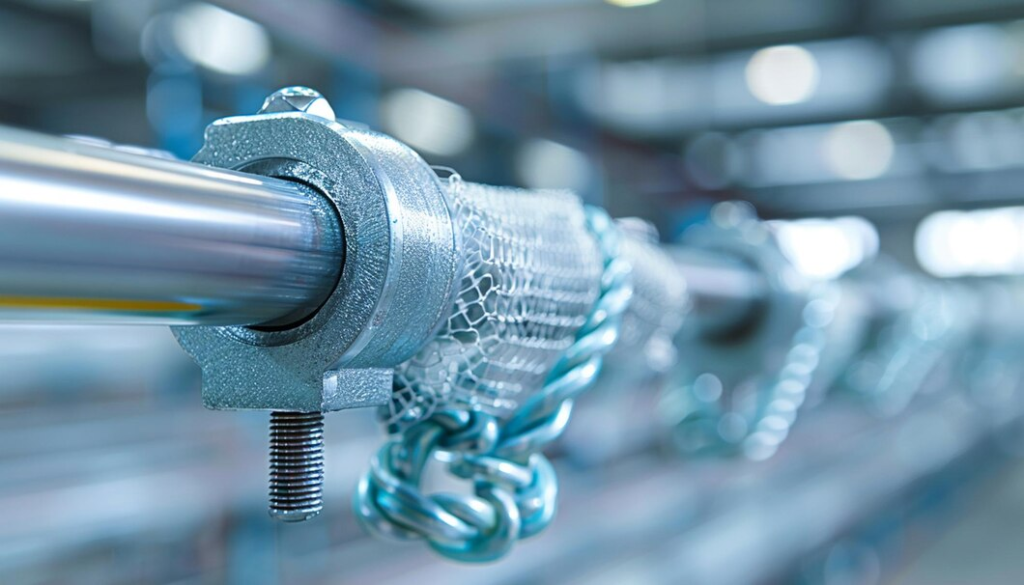

Introduction to Industrial Automation Parts

Industrial automation involves the use of control systems, such as computers and robots, and information technologies for handling different processes and machinery in an industry. Automation components include sensors, actuators, control systems, and software, which work together to streamline manufacturing processes. By integrating these parts, manufacturers can reduce human intervention, minimize errors, and increase output.

NOTE: Looking for reliable industrial automation parts suppliers in UAE? Apex Global Solutions ME offers top-quality components to ensure your systems run smoothly and efficiently. Trust our expertise and extensive inventory. Contact us today to learn more about our products and services!

For instance, consider a factory that produces automotive parts. By implementing automation systems, the factory can ensure that each part is manufactured to precise specifications. Sensors can detect any deviations in the production process, while actuators can make necessary adjustments in real-time. This level of precision not only improves the quality of the products but also reduces waste and rework, leading to cost savings.

Enhanced Precision and Quality Control

One of the significant benefits of industrial automation parts is the enhancement of precision and quality control in manufacturing processes. Automated systems can perform tasks with a level of accuracy that is difficult for humans to achieve consistently. For example, robotic arms equipped with advanced sensors can assemble intricate components with micron-level precision.

Imagine a scenario where you are manufacturing electronic devices that require precise placement of tiny components on circuit boards. Manual assembly can lead to errors and inconsistencies, affecting the performance of the devices. However, by using automated systems, you can ensure that each component is placed accurately, resulting in higher quality products.

Moreover, automated systems can continuously monitor the production process and identify any defects or deviations from the desired specifications. This real-time monitoring allows for immediate corrective actions, reducing the likelihood of defective products reaching the market. As a result, manufacturers can maintain high-quality standards and enhance their reputation for reliability.

Increased Production Speed

Industrial automation parts significantly increase production speed by streamlining various manufacturing processes. Automated systems can operate at a much faster pace than humans, enabling manufacturers to produce more goods in a shorter amount of time. This increased speed is particularly beneficial in industries with high demand and tight production schedules.

For instance, in the food and beverage industry, automated packaging machines can rapidly fill, seal, and label products, ensuring a consistent and efficient packaging process. This not only reduces the time required for packaging but also minimizes the risk of contamination and ensures compliance with hygiene standards.

Additionally, automated systems can work around the clock without the need for breaks, unlike human workers. This continuous operation maximizes productivity and allows manufacturers to meet tight deadlines. By leveraging industrial automation parts, you can scale up production to meet growing market demands without compromising on quality or efficiency.

Reduced Labor Costs and Enhanced Safety

Another significant advantage of industrial automation parts is the reduction in labor costs. By automating repetitive and labor-intensive tasks, manufacturers can reduce their dependence on manual labor. This not only lowers labor costs but also frees up human workers to focus on more complex and value-added activities.

Consider a manufacturing plant that produces heavy machinery components. Manually handling these components can be physically demanding and pose safety risks to workers. However, by implementing automation systems, such as robotic arms and conveyor belts, you can eliminate the need for manual lifting and reduce the risk of workplace injuries.

Moreover, automated systems can operate in hazardous environments, such as extreme temperatures or toxic atmospheres, where human presence is not safe. This enhances workplace safety and ensures compliance with occupational health and safety regulations. By prioritizing the safety of your workers, you can create a more productive and motivated workforce.

Improved Consistency and Reliability

Consistency and reliability are critical factors in manufacturing processes. Industrial automation parts excel in delivering consistent and reliable performance, ensuring that each product meets the desired specifications. Unlike human workers, automated systems do not experience fatigue, distractions, or variations in performance.

For example, in the pharmaceutical industry, precise dosage and accurate labeling are essential to ensure the safety and efficacy of medications. Automated systems can fill and label medication bottles with high precision, eliminating the risk of dosage errors and incorrect labeling. This level of consistency and reliability is crucial for maintaining regulatory compliance and ensuring customer safety.

Furthermore, automated systems can perform repetitive tasks with the same level of accuracy and efficiency every time. This consistency reduces the likelihood of defects and rework, leading to cost savings and improved overall efficiency. By relying on industrial automation parts, you can achieve a higher level of consistency and reliability in your manufacturing processes.

Real-Time Data and Analytics

Industrial automation parts enable manufacturers to collect and analyze real-time data from their production processes. This data provides valuable insights into various aspects of manufacturing, such as machine performance, production rates, and quality metrics. By leveraging this data, you can make informed decisions and optimize your manufacturing operations.

For instance, consider a scenario where you are producing consumer electronics. By analyzing real-time data from your automated systems, you can identify bottlenecks in the production process and take corrective actions to improve efficiency. Additionally, you can monitor the performance of individual machines and schedule maintenance activities proactively, reducing the risk of unexpected breakdowns and minimizing downtime.

Moreover, real-time data and analytics enable predictive maintenance, where you can predict potential equipment failures and address them before they occur. This approach not only reduces downtime but also extends the lifespan of your equipment, resulting in long-term cost savings. By harnessing the power of data and analytics, you can continuously improve your manufacturing processes and stay ahead of the competition.

Flexibility and Adaptability

Industrial automation parts offer flexibility and adaptability to manufacturers, allowing them to respond quickly to changing market demands. Automated systems can be reprogrammed and reconfigured to accommodate different product variations and production requirements. This flexibility is particularly valuable in industries with rapidly evolving product designs and customer preferences.

For example, in the automotive industry, manufacturers often need to produce different models and variants of vehicles on the same production line. By using automated systems, you can easily switch between different production setups and adjust the manufacturing process accordingly. This flexibility reduces the time and cost associated with retooling and enables you to bring new products to market faster.

Additionally, automated systems can be integrated with other advanced technologies, such as artificial intelligence and machine learning, to enhance their adaptability. These technologies can analyze historical data and optimize production parameters in real-time, further improving efficiency and responsiveness. By embracing industrial automation parts, you can create a more agile and adaptable manufacturing operation.

Sustainability and Environmental Benefits

Industrial automation parts also contribute to sustainability and environmental benefits in manufacturing. By optimizing production processes and reducing waste, automated systems help manufacturers minimize their environmental footprint. This is particularly important in today’s world, where sustainability and environmental responsibility are becoming increasingly significant.

For instance, automated systems can precisely control the amount of raw materials used in production, reducing material waste. Additionally, they can optimize energy consumption by adjusting machine operations based on real-time demand. These measures not only lower operating costs but also reduce greenhouse gas emissions and promote sustainable manufacturing practices.

Moreover, automated systems can facilitate the implementation of recycling and reusability initiatives. By efficiently sorting and processing recyclable materials, manufacturers can reduce the amount of waste sent to landfills. This contributes to a circular economy and aligns with global efforts to reduce waste and conserve resources.

Conclusion: Embracing Industrial Automation for a Competitive Edge

In conclusion, industrial automation parts play a pivotal role in improving efficiency in manufacturing. By enhancing precision and quality control, increasing production speed, reducing labor costs, and improving safety, automated systems offer numerous benefits to manufacturers. Additionally, they provide consistency and reliability, enable real-time data and analytics, offer flexibility and adaptability, and contribute to sustainability and environmental benefits.

As a manufacturer, embracing industrial automation parts can give you a competitive edge in the market. By leveraging the power of automation, you can streamline your operations, reduce costs, and deliver high-quality products to your customers. Furthermore, automation allows you to stay agile and responsive to changing market demands, ensuring long-term success.

Investing in industrial automation is not just about adopting the latest technology; it’s about transforming your manufacturing processes and creating a more efficient and sustainable future. Whether you are a small business or a large corporation, the benefits of industrial automation are undeniable. By incorporating automation components into your manufacturing operations, you can achieve higher levels of efficiency, productivity, and profitability.

So, if you haven’t already, it’s time to explore the potential of industrial automation parts and take your manufacturing processes to the next level. Embrace the future of manufacturing, and let automation drive your success.

For More Isightful Articles Related To This Topic, Feel Free To Visit: usafulnews