The Evolution of Robotics in Modern Assembly Line Systems

Assembly line systems have undergone a remarkable transformation with the integration of robotics, revolutionizing manufacturing processes across industries. This blog delves into the evolution of robotics in modern assembly line systems, exploring key advancements, benefits, challenges, and future trends shaping the manufacturing landscape.

The Rise of Robotics in Assembly Line Systems

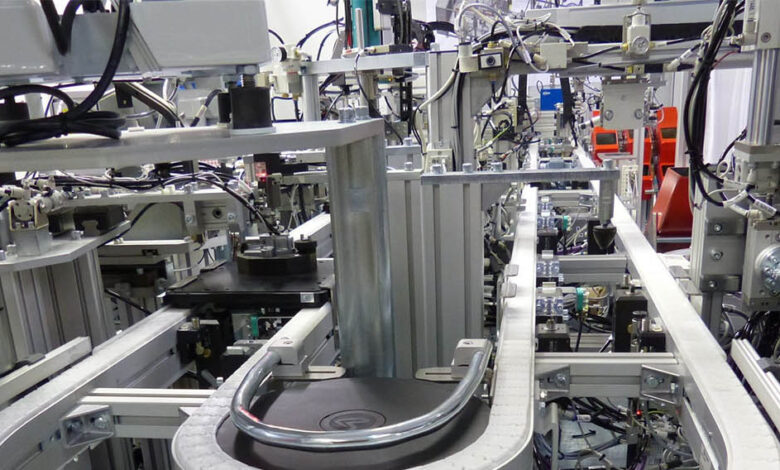

Assembly line systems historically relied on manual labor and basic mechanization. However, the advent of robotics introduced unprecedented levels of automation, precision, and efficiency. Robotics in assembly line systems encompass a wide range of applications, from simple pick-and-place tasks to complex assembly operations involving intricate components.

Key Advancements in Robotics for Assembly Line Systems

- Industrial Robots: Traditional industrial robots, such as articulated arms and gantry robots, revolutionized assembly line operations by performing repetitive tasks with high speed and accuracy.

- Collaborative Robots (Cobots): Cobots emerged as a game-changer by working alongside human operators, enhancing flexibility, and ensuring safety in dynamic assembly environments.

- Vision Systems and AI: Integration of vision systems and artificial intelligence (AI) enables robots to identify and handle objects, navigate complex environments, and adapt to variations in production processes.

- Mobile Robotics: Autonomous mobile robots (AMRs) facilitate material handling, logistics, and assembly tasks, enhancing agility and operational efficiency in assembly line systems.

Benefits of Robotics in Assembly Line Systems

- Improved Efficiency: Robots perform tasks with consistent precision and speed, minimizing cycle times and increasing throughput in assembly operations.

- Enhanced Safety: Cobots equipped with sensors and advanced safety features collaborate safely with human workers, reducing workplace accidents and ergonomic risks.

- Quality Assurance: Robotics enhance product quality through precise assembly, accurate positioning, and real-time quality control inspections, minimizing defects and ensuring compliance with stringent standards.

- Cost Efficiency: Over time, robotics in assembly line systems contribute to cost savings by reducing labor costs, optimizing resource utilization, and minimizing operational downtime.

Challenges and Considerations

While robotics offer substantial benefits, their implementation in assembly line systems comes with challenges:

- Initial Investment: High upfront costs for robotics integration, including equipment, training, and infrastructure modifications.

- Integration Complexity: Adapting existing assembly line layouts and processes to accommodate robotics requires careful planning and integration expertise.

- Maintenance and Support: Ensuring continuous operation and addressing maintenance needs of robotic systems to prevent disruptions in production.

Future Trends and Innovations

Looking ahead, the evolution of robotics in assembly line systems is poised for continued advancements:

- AI-driven Robotics: AI algorithms will enhance robots’ learning capabilities, enabling adaptive decision-making and autonomous operation.

- Advanced Sensing Technologies: Integration of advanced sensors, IoT connectivity, and real-time data analytics for predictive maintenance and performance optimization.

- Flexible Automation: Robotics will become more flexible and adaptable to handle diverse product configurations and changing production demands.

Case Studies: Successful Applications of Robotics in Assembly Line Systems

- Automotive Manufacturing: Leading automotive manufacturers utilize robots for welding, painting, and assembly of vehicles, achieving high precision and production efficiency.

- Electronics Assembly: Electronics companies deploy robotics for delicate assembly tasks, such as PCB handling and component placement, ensuring quality and consistency.

Conclusion

The evolution of robotics in modern assembly line systems represents a transformative shift towards automation, precision, and efficiency in manufacturing. By leveraging robotics, businesses can enhance productivity, ensure product quality, and adapt to the demands of a competitive global market.

Embrace the opportunities presented by robotics in assembly line systems to drive innovation, streamline operations, and achieve sustainable growth. By investing in advanced technologies, prioritizing safety and quality, and fostering a culture of continuous improvement, manufacturers can navigate challenges and seize new possibilities in the evolving landscape of modern manufacturing.

Prepare your assembly line systems for the future with robotics as a cornerstone of automation and efficiency. Embrace innovation, optimize processes, and unlock new potentials for success in manufacturing.