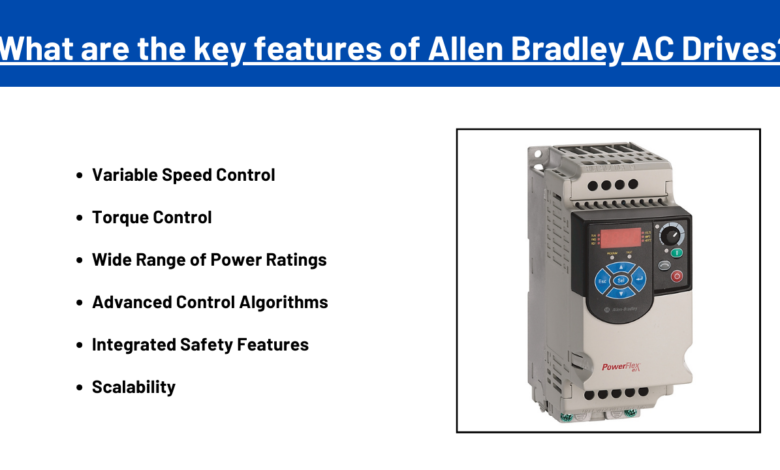

What are the key features of Allen Bradley AC Drives?

High-performance motor control solutions are provided by Allen Bradley AC Drives and are intended for a variety of industrial applications. Electric motor performance is maximized and efficient operation is guaranteed by Allen Bradley AC Drives because to its sophisticated features including torque regulation, precise speed control, and sturdy design. Pre-installed adaptability makes it easy to integrate into other systems, while sophisticated monitoring and diagnostics improve dependability and make maintenance easier.

Variable Speed Control:

Accurate motor speed control is made possible by AC drives, which promotes process optimization and energy efficiency.

- Precision Control: Users may precisely control the speed of AC motors with AC drives, allowing them to modify the motor speed to suit the needs of the application. Achieving targeted performance levels and process optimization depend on this fine management.

- Flexible Speed Range: Motors can run at a variety of rates because to the broad speed control provided by Allen Bradley AC drives, from extremely low to extremely high. Because of their adaptability, they may be used in a wide range of sectors for things like fans, pumps, and conveyor systems.

- Smooth Acceleration and Deceleration: Smooth acceleration and deceleration of motors is made possible by AC drives, which lessen mechanical stress on the machinery and guarantee smooth functioning. This capability is especially crucial for programs that need to start and stop often.

- Adaptive Speed Control: Adaptive speed control algorithms are found in certain Allen Bradley AC drives, which automatically modify motor speed in response to changes in load or other external variables. The system’s overall performance is enhanced and energy usage is optimized with the aid of adaptive control.

- Speed Presets and Profiles: The ability to save and recall speed presets or profiles is a feature of many AC drives that makes it simple to transition between various operating modes or process requirements without requiring human modifications.

Torque Control:

They give the motor’s torque output control, which is crucial for applications needing different amounts of force.

- Precise Torque Regulation: Users can precisely regulate the torque output of AC motors with Allen Bradley AC drives. This is necessary in applications where performance and safety depend on maintaining a particular torque level.

- Torque Limiting: Users of AC drives can establish torque limits to make sure motors don’t run over preset torque thresholds. This function improves system safety and shields equipment from harm brought on by excessive torque.

- Torque Boost: A few AC drives have the ability to momentarily raise motor torque in order to overcome high loads of inertia or accelerate heavy loads more quickly. In demanding workloads, this feature improves the drive’s performance.

- Torque Compensation: Torque compensation algorithms can be used by Allen Bradley AC drives to modify motor torque in response to changes in load, temperature, or speed. This guarantees steady torque production in the face of fluctuating operational circumstances.

Wide Range of Power Ratings:

To accommodate varying motor sizes and application requirements, Allen Bradley offers AC drives in a range of power ratings.

Advanced Control Algorithms:

For exact motor control, these drives frequently use complex control algorithms like flux vector control and sensorless vector control.

Also Read :- Allen Bradley PowerFlex 4M AC drives

Integrated Safety Features:

To ensure safe operation in industrial situations, many Allen Bradley AC drives come equipped with built-in safety features including Safe Torque Off (STO) and Safe Speed Monitoring.

- Safe Torque Off (STO): When the safety circuit is triggered, the STO safety function makes sure the motor stops safely and stays in a torque-free state. STO feature is frequently used in Allen Bradley AC drives to stop unexpected motor running during emergencies or maintenance.

- Safe Speed Monitoring: This function helps to prevent overspeed situations that could endanger people or property by monitoring motor speed and ensuring that it stays within safe bounds. In applications where high-speed operation is a problem, safe speed monitoring is essential.

- Emergency Stop (E-Stop) Functionality: Emergency stop functionality is supported by Allen Bradley AC drives, enabling operators to instantly stop motor running in an emergency. This feature reduces the risk of mishaps and lessens product or equipment damage.

- Safety Interlocks: Safety interlock systems can be integrated with AC drives to make sure that specific requirements are satisfied before allowing motor activation. For instance, before the motor starts, interlocks might demand that safety gates be closed or that people be present in specified safe zones.

Communication Protocols:

Their compatibility with multiple communication protocols, including DeviceNet, Ethernet/IP, and Modbus TCP/IP, facilitates their easy incorporation into industrial networks and control systems.

Scalability:

Because of their scalability, customers can add more drives or modules to their control systems as needed to improve or expand them.

- Modular Design: A modular architecture included in many Allen Bradley AC drives enables customers to add or remove modules as needed. By allowing the system to adapt to changes in power needs, communication protocols, or additional capabilities without having to replace the entire drive, this modular architecture promotes scalability.

- Expansion Options: Adding more modules or accessories is made possible by the expansion slots or ports that Allen Bradley AC drives frequently include. The drive’s functionality can be increased by users by adding modules for features like more I/O, communication interfaces, or sophisticated control capabilities.

- Network Integration: Allen Bradley AC drives can be easily integrated into industrial networks like DeviceNet, ControlNet, or Ethernet/IP. The drives may communicate with other devices and control systems thanks to this network integration, which promotes scalability by enabling the extension of the network infrastructure or the addition of additional devices.

In many different industrial applications, Allen Bradley AC drives provide a complete motor control solution. The enhanced efficiency, dependability, and security of industrial operations are facilitated by their precise control, sophisticated features, sturdy construction, and broad support. Allen Bradley AC drives provide the efficiency and adaptability needed in contemporary industrial settings, regardless of the complexity of the system or application.

When you require variable frequency drives for your manufacturing industry system, Asteam Techno Solutions Pvt Ltd is here to help you. With an inventory of obsolete and surplus spare parts and a team of qualified engineers, there’s no breakdown or fault we cannot solve. Wherever you are in the world, Asteam Techno Solutions Pvt Ltd is the best Industrial Automation parts supplier and solutions provider in India as well as globally. Get support for all types of equipment from AC, DC and servo drives through to PLCs, HMIs and other automation parts. Hard to find parts are a specialty, with fast shipping on obsolete parts from all brands including Allen Bradley, Mitsubishi, Omron, Siemens, Schneider, Moxa, VIPA and more.