A Comprehensive Guide to Insulated Aluminum Roof Panels

Insulated aluminum roof panels are becoming increasingly popular in modern construction, offering a range of benefits that make them an attractive option for residential, commercial, and industrial buildings. These panels combine the durability and lightweight properties of aluminum with the insulating properties of various core materials, resulting in a roofing solution that provides superior thermal performance, energy efficiency, and structural integrity. This comprehensive guide will explore the various aspects of insulated aluminum roof panels, including their composition, benefits, applications, installation processes, and maintenance considerations.

Composition of Insulated Aluminum Roof Panels

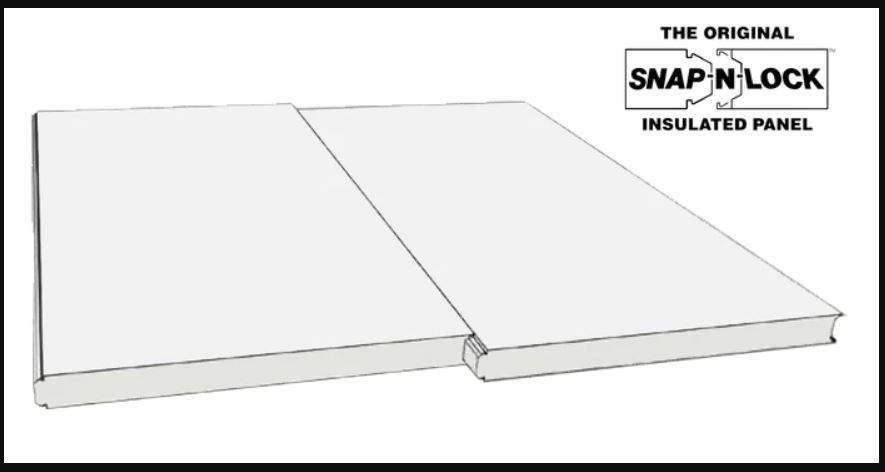

Insulated aluminum roof panels typically consist of three main layers: the aluminum outer layers and the insulating core. The outer layers are usually made of aluminum sheets, which can be coated or treated for additional protection against corrosion, UV radiation, and other environmental factors. The core material is often made of expanded polystyrene (EPS), polyurethane (PUR), polyisocyanurate (PIR), or mineral wool, each offering different levels of thermal insulation and fire resistance.

Aluminum Sheets: The aluminum sheets used in these panels are lightweight yet strong, providing excellent structural support. They can be pre-painted or coated with a protective layer to enhance their durability and aesthetic appeal.

Insulating Core: The core material is crucial for the panel’s thermal performance. EPS is a common choice due to its cost-effectiveness and adequate insulation properties. PUR and PIR offer higher insulation values and better fire resistance, making them suitable for buildings with stricter energy efficiency and safety requirements. Mineral wool, known for its excellent fire-resistant properties, is ideal for applications where fire safety is paramount.

Benefits of Insulated Aluminum Roof Panels

Insulated aluminum roof panels offer numerous advantages that make them a preferred choice for many construction projects. Some of the key benefits include:

Energy Efficiency: The insulating core significantly reduces heat transfer, helping to maintain a consistent indoor temperature. This leads to lower energy consumption for heating and cooling, resulting in reduced utility bills and a smaller carbon footprint.

Durability and Longevity: Aluminum is resistant to rust, corrosion, and environmental degradation, ensuring a long lifespan for the roof panels. The protective coatings further enhance their durability, making them suitable for various climates and weather conditions.

Lightweight and Easy Installation: Despite their strength, aluminum panels are lightweight, making them easier to handle and install. This reduces labor costs and installation time compared to traditional roofing materials.

Fire Resistance: Depending on the core material, insulated aluminum roof panels can offer excellent fire resistance. This is particularly important for commercial and industrial buildings where fire safety is a critical concern.

Aesthetic Versatility: These panels come in various colors, finishes, and profiles, allowing architects and builders to achieve the desired aesthetic for their projects. They can mimic the appearance of traditional roofing materials while providing modern performance benefits.

Environmental Sustainability: Aluminum is a recyclable material, contributing to the sustainability of construction projects. Additionally, the energy savings achieved through improved insulation further enhance the environmental benefits.

Applications of Insulated Aluminum Roof Panels

Insulated aluminum roof panels are versatile and can be used in a wide range of applications, including:

Residential Buildings: These panels are ideal for residential roofs, offering homeowners a durable, energy-efficient, and aesthetically pleasing roofing solution. They can be used for new constructions or roof replacements.

Commercial Buildings: For commercial properties such as offices, retail spaces, and hotels, insulated aluminum roof panels provide the necessary thermal performance and fire resistance.

Industrial Buildings: In industrial settings, these panels offer robust performance under harsh conditions. They are suitable for warehouses, factories, and other facilities that require durable and fire-resistant roofing solutions.

Agricultural Structures: Insulated aluminum roof panels are also used in agricultural buildings, such as barns and storage facilities, where temperature regulation and durability are crucial.

Public and Institutional Buildings: Schools, hospitals, and other public buildings benefit from the energy efficiency, fire safety, and longevity of insulated aluminum roof panels.

Installation Process

The installation of insulated aluminum roof panels involves several key steps to ensure a secure and efficient roofing system. Here is an overview of the typical installation process:

Preparation: The roof structure must be inspected and prepared for the installation. This includes ensuring the surface is clean, dry, and free of any debris that could affect the adhesion of the panels.

Measuring and Cutting: Accurate measurements are taken to cut the panels to the required size. This step is crucial for ensuring a precise fit and minimizing material wastage.

Laying the Panels: The panels are laid out on the roof structure, starting from the bottom edge and working upwards. Each panel is secured to the structure using appropriate fasteners, ensuring they are firmly in place.

Sealing Joints: To prevent water infiltration and enhance thermal performance, the joints between panels are sealed using weatherproof sealants or gaskets. This step is critical for maintaining the integrity of the roofing system.

Maintenance Considerations

Insulated aluminum roof panels require minimal maintenance compared to traditional roofing materials. However, regular inspections and basic upkeep are essential to ensure their longevity and performance. Here are some maintenance tips:

Regular Inspections: Periodic inspections should be conducted to check for any signs of damage, such as dents, scratches, or corrosion. Early detection allows for timely repairs and prevents further deterioration.

Cleaning: The panels should be cleaned periodically to remove dirt, debris, and other contaminants. Mild detergents and water are usually sufficient for cleaning, but harsh chemicals should be avoided to prevent damage to the protective coatings.

Conclusion

Insulated aluminum roof panels represent a modern, efficient, and versatile roofing solution suitable for various building types and applications. Their combination of energy efficiency, durability, fire resistance, and aesthetic appeal makes them a valuable investment for any construction project. By understanding their composition, benefits, installation process, and maintenance requirements, builders and property owners can make informed decisions and maximize the advantages of this innovative roofing technology.