Composite Column Design: Enhancing Structural Integrity and Aesthetic Appeal with Melton Classics

Introduction

Composite columns are a vital component in modern architecture and construction, offering a blend of strength, durability, and aesthetic flexibility. These columns combine different materials to create structures that are not only robust but also visually appealing. At Melton Classics, we specialize in designing and manufacturing high-quality composite columns that meet the diverse needs of our clients. In this article, we’ll explore the concept of composite column design, its benefits, and why it’s an excellent choice for your next construction project.

What Are Composite Columns?

Composite columns are structural elements that consist of two or more different materials combined to utilize the best properties of each. Typically, these Composite columns design are made from a combination of concrete and steel, but other materials such as fiberglass, carbon fiber, and polymers can also be used. The goal is to enhance the overall performance of the column in terms of strength, durability, and aesthetic appeal.

Benefits of Composite Columns

Strength and Durability: The combination of materials in composite columns results in superior strength and durability compared to traditional columns made from a single material. For instance, steel provides excellent tensile strength, while concrete offers high compressive strength.

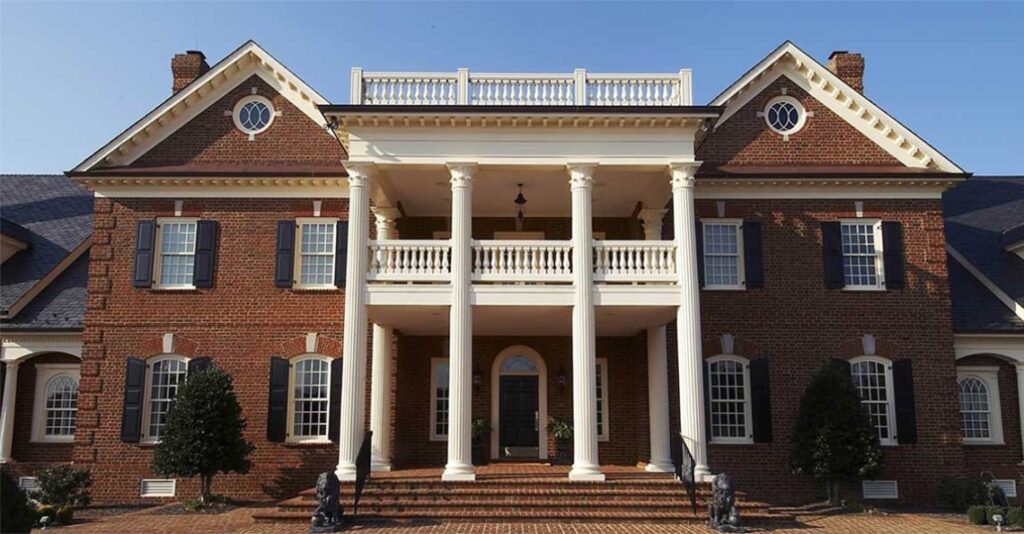

Aesthetic Flexibility: Composite columns can be designed to mimic various architectural styles and finishes. Whether you prefer a classic look or a modern design, composite columns can be customized to suit your preferences.

Cost-Effective: Using composite materials can often be more cost-effective than using a single material, particularly when considering the long-term benefits of reduced maintenance and increased lifespan.

Lightweight: Certain composite materials, such as fiberglass or carbon fiber, are much lighter than traditional materials, making them easier to handle and install without compromising strength.

Environmental Benefits: Composite columns can incorporate recycled materials, contributing to sustainable building practices.

Types of Composite Columns

Steel-Concrete Composite Columns: These are the most common type, combining the high tensile strength of steel with the compressive strength of concrete. They are ideal for high-rise buildings and structures requiring significant load-bearing capacity.

Fiberglass-Concrete Composite Columns: Fiberglass provides lightweight and corrosion-resistant properties, making these columns suitable for environments exposed to harsh weather conditions.

Timber-Concrete Composite Columns: These columns combine the natural aesthetic of wood with the strength and durability of concrete, offering a unique blend of beauty and functionality.

Polymer-Concrete Composite Columns: Polymers enhance the flexibility and resilience of concrete, making these columns suitable for specialized architectural applications.

Design Considerations for Composite Columns

Load-Bearing Capacity: Understanding the load requirements is crucial in designing composite columns. The combination of materials should be chosen to optimize the column’s ability to bear loads without compromising safety.

Environmental Factors: Consider the environment where the column will be installed. Factors like humidity, temperature fluctuations, and exposure to chemicals can influence the choice of materials.

Aesthetic Requirements: The design should align with the overall architectural style of the building. Composite columns can be finished in various textures and colors to match or contrast with the surrounding elements.

Maintenance Needs: Different materials have varying maintenance requirements. Ensure that the chosen materials will provide a balance between durability and ease of maintenance.

Installation Process

Planning and Design: Begin with detailed planning and design, taking into account the structural and aesthetic requirements. At Melton Classics, we work closely with architects and engineers to create customized designs that meet specific project needs.

Fabrication: The composite materials are fabricated according to the design specifications. This involves precise cutting, shaping, and assembling of the materials.

Transportation and Handling: Composite columns are transported to the construction site. Due to their lightweight nature, they are easier to handle and less likely to cause damage during transit.

Installation: The columns are installed by securing them to the foundation and ensuring they are properly aligned. This process may involve welding, bolting, or using adhesives, depending on the materials used.

Finishing Touches: After installation, the columns are finished with the desired texture, color, or additional detailing to enhance their aesthetic appeal.

Maintaining Composite Columns

Regular Inspections: Conduct regular inspections to identify any signs of wear or damage. Early detection can prevent minor issues from becoming major problems.

Cleaning: Use appropriate cleaning methods for the materials involved. For example, mild soap and water are typically sufficient for fiberglass, while concrete may require periodic power washing.

Protective Coatings: Applying protective coatings can enhance the durability and appearance of composite columns, especially in harsh environmental conditions.

Cost Considerations

The cost of composite columns can vary based on the materials used and the complexity of the design. While the initial cost may be higher than traditional columns, the long-term savings in maintenance and durability often offset this. At Melton Classics, we offer competitive pricing and work with clients to find solutions that fit their budgets without compromising quality.

Applications of Composite Columns

Residential Buildings: Composite columns can add elegance and strength to homes, whether used in porches, verandas, or interior spaces.

Commercial Structures: From office buildings to shopping malls, composite columns provide the necessary support and aesthetic appeal for large-scale commercial projects.

Historic Restorations: Composite columns are ideal for restoring historic buildings, offering modern strength while maintaining the original architectural integrity.

Public Infrastructure: Bridges, walkways, and public buildings benefit from the durability and low maintenance of composite columns.

Why Choose Melton Classics for Composite Columns

At Melton Classics, we pride ourselves on delivering superior quality and exceptional design. Our composite columns are crafted with precision and care, ensuring they meet the highest standards of strength, durability, and aesthetic appeal. We offer customized solutions tailored to the unique needs of each project, backed by our commitment to customer satisfaction.

Conclusion

Composite columns represent the future of construction, combining the best properties of different materials to create structures that are strong, durable, and visually stunning. At Melton Classics, we are dedicated to providing top-quality composite columns that enhance the beauty and functionality of your buildings. Whether you’re working on a new construction project or renovating an existing structure, our composite columns offer a versatile and cost-effective solution.

FAQs

What are composite columns? Composite columns are structural elements made from a combination of materials, typically to enhance strength and aesthetic appeal.

Why are composite columns beneficial? They offer superior strength, durability, aesthetic flexibility, and can be more cost-effective and environmentally friendly than traditional columns.

How do you maintain composite columns? Regular inspections, appropriate cleaning methods, and protective coatings can help maintain the integrity and appearance of composite columns.

Where are composite columns commonly used? They are used in residential buildings, commercial structures, historic restorations, and public infrastructure projects.